|

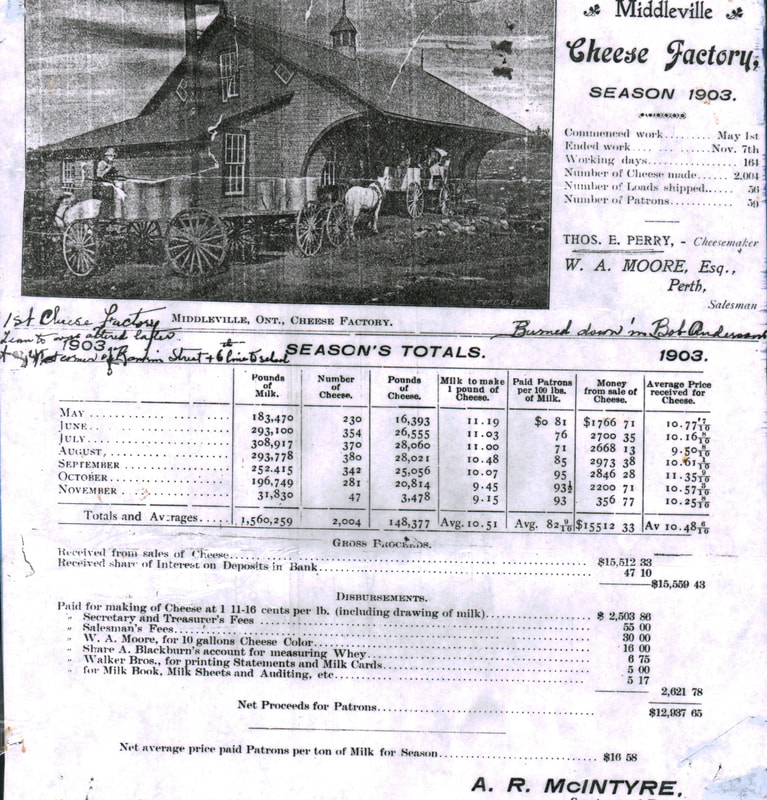

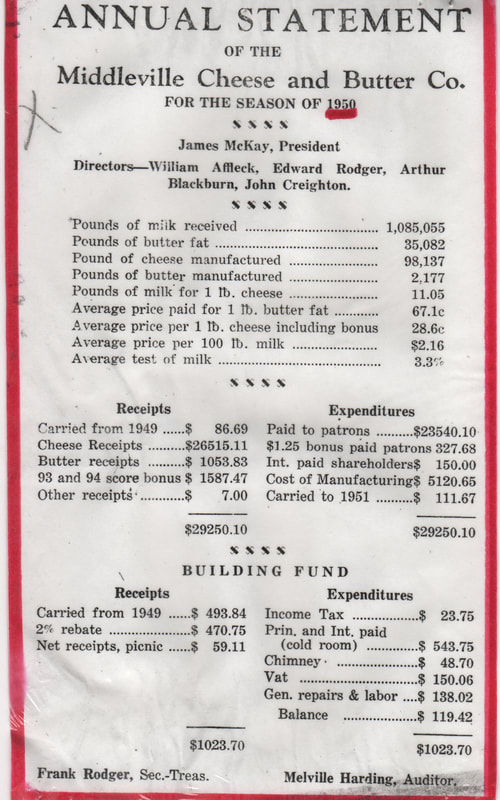

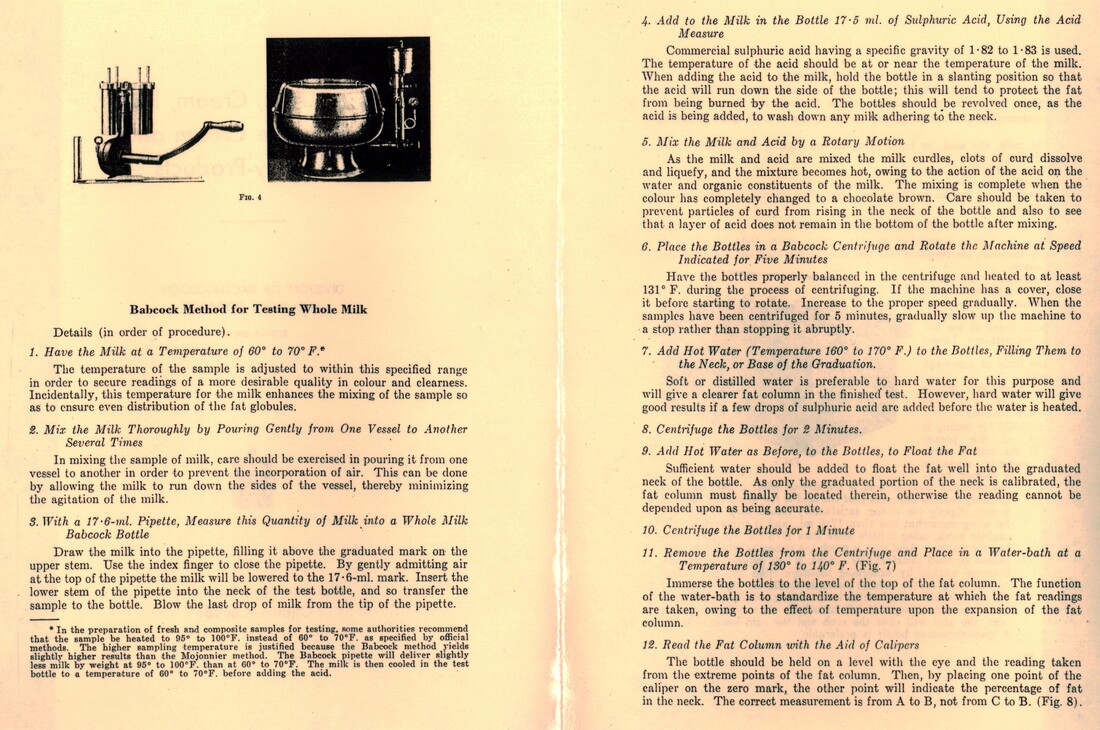

Up until 1900, all farmers received the same price for their milk. They were paid by the weight of their milk. This was known as the ‘pooling system’. This encouraged farmers to supply the cheese factory with as much milk as possible. Milk wasn’t shipped on Sundays so this resulted on low cheese scores on Monday as the milk was not as fresh. In June 1900, 15 600 pounds of milk was delivered to the Middleville Cheese Factory in a day. Dr. Stephen Mouton Babcock (1842-1931), an American Agricultural Chemist had developed a precise method for determining the butterfat content of milk in 1890. He donated his test to the dairy industry rather than obtaining a patent and profiting from it on his own. A small sample of each farmer’s milk was ladled into a numbered bottle for butterfat content testing purposes. A Holstein was able to produce milk with a butterfat content of 4%. Middleville Cheese Factory Report of 1933 reported 770 042 delivered to the factory by local patrons. The average price paid to farmers for their butterfat during the season was 17 cents per pound. The Middleville and District Museum has many artifacts used over the decades in milk testing and production. There are many booklets and pamphlets on techniques of milk, butter and cheese production in earlier days. Be sure to browse the exhibit on your next visit.

0 Comments

Leave a Reply. |

AuthorThis journal is written, researched, and maintained by the volunteers of the Middleville Museum. |