|

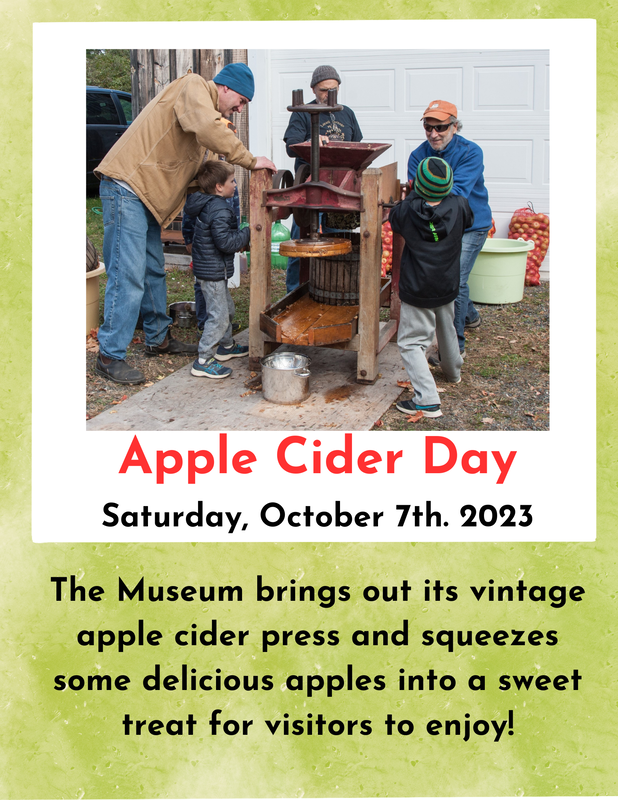

Although fruit presses were used before the 1900's, it was in 1916 that Madeline Turner sought a patent for a fruit press that would both chop and press apples. 'Cider mill' is actually considered the proper term if both the chopper and press are together in one machine as the Museum's press has. Sweet and tart apples are washed and then roughly chopped. Next they are placed into the chopper at the top. As they are directed downwards onto 'teeth', the apples become ground into pulp. The teeth are activated by turning the cranks on the sides. When the wooden barrel is partially full of apple pulp, it is moved underneath the pressing plate attached to the long, iron shaft. The iron wheel at the top of the shaft is turned and the plate moves down onto the pulp and squeezes the juice out. The liquid runs down the wooden trough and into a vessel placed below. The juice oxidizes into an amber colour. Froth that forms on the surface can be skimmed off. People wanting to pasteurize apple cider usually heat the cider to 160 degrees F for several seconds. It can also be frozen to be enjoyed at a later date. 30 - 40 apples will usually produce about one gallon of cider. Mulled Apple Cider 1 gallon cider 8 - 10 whole cloves 3 cinnamon sticks, broken 1 lemon or orange, sliced 2 inch piece of fresh ginger, cut into thick slices Combine into large pot. Simmer 30 minutes. Strain with a fine sieve. The Middleville and District Museum will once again bring out its vintage apple cider press and welcome visitors to enjoy the taste of fall.

Join the fun on Saturday, October 7th, from noon - 4pm at this free family friendly event. There will be apple treats, live music and crafts for kids. Note: In the case of rain, the event will take place in our large, event.

0 Comments

Leave a Reply. |

AuthorThis journal is written, researched, and maintained by the volunteers of the Middleville Museum. |